Optimizing Production Speed and Filament Denier for Custom PP Spunbond Nonwoven Fabric Quality

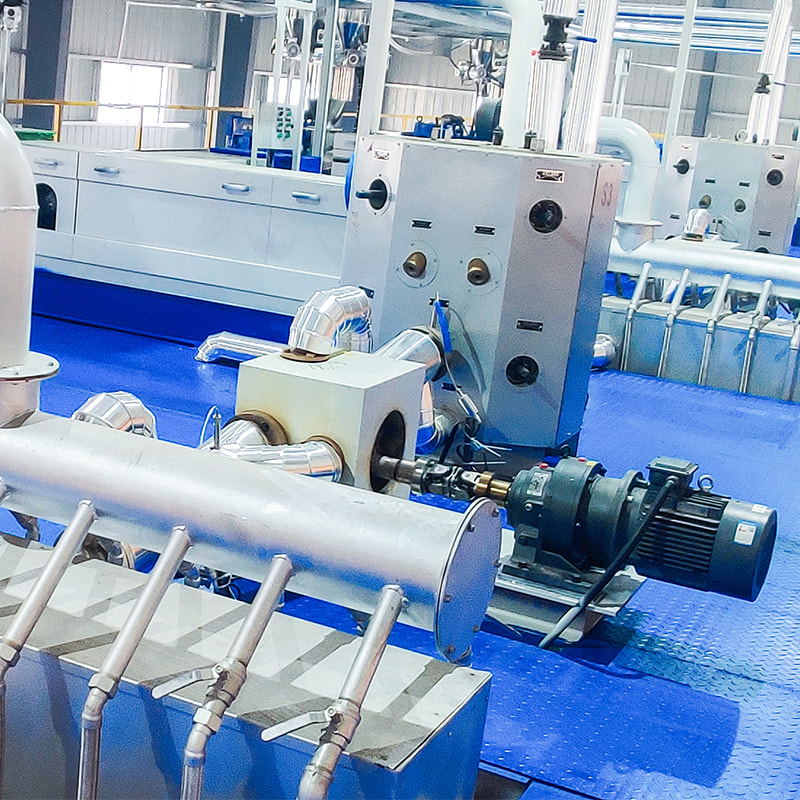

The ability to fine-tune the production speed and filament denier of a nonwoven fabric machine plays a crucial role in determining the final quality of the fabric. For manufacturers of PP spunbond nonwoven fabrics, the SMMSS nonwoven fabric machine offers unparalleled flexibility, allowing them to adjust production speeds from 10 to 350 meters per minute. This range of speeds provides a critical advantage for achieving various fabric characteristics, depending on specific application requirements. Whether the goal is to produce high-density fabrics for medical textiles or lighter materials for hygiene products, controlling these parameters can have a significant impact on both performance and material properties.

Filament denier, typically ranging from 1.8 to 2.3 denier on the SMMSS nonwoven fabric machine, also plays a vital role in determining the fabric’s strength, softness, and overall texture. Denier refers to the weight in grams of 9,000 meters of a single filament, and by adjusting this setting, manufacturers can control how thick or thin the individual fibers in the nonwoven fabric are. Fabrics with a lower denier tend to be softer and more flexible, making them ideal for products like diapers and medical gowns. On the other hand, higher denier fabrics are typically more durable and resistant to wear, making them suitable for heavy-duty applications such as geotextiles or automotive components.

The interaction between production speed and filament denier is complex. When the machine operates at higher speeds, there’s a natural tendency for the filament to become thinner due to the faster extrusion process. However, balancing the machine's speed with the appropriate denier ensures that the final fabric maintains a consistent quality. The SMMSS nonwoven fabric machine is designed to accommodate these variables, giving manufacturers the control they need to produce a diverse range of nonwoven fabrics. The ability to adjust these two parameters ensures that manufacturers can meet the exact specifications demanded by customers, resulting in less waste and more efficient production cycles.

The fabric's final quality is also influenced by how well the machine maintains consistent filament production throughout the process. A high level of precision is necessary to prevent irregularities that could affect the strength, texture, or appearance of the finished product. With its state-of-the-art CNC-driven production capabilities, the SMMSS nonwoven fabric machine ensures that each part of the production process is meticulously crafted for maximum precision. This high degree of control over both speed and denier ensures that manufacturers can produce fabrics with predictable and reliable characteristics, meeting the stringent standards of various industries.

Ultimately, the combination of flexible production speed and customizable filament denier on the SMMSS nonwoven fabric machine offers manufacturers a powerful tool for creating PP spunbond nonwoven fabrics that meet the exacting demands of their customers. By mastering these settings, businesses can optimize their production processes, reduce material waste, and increase output efficiency. This level of customization not only enhances product quality but also positions manufacturers as leaders in the competitive nonwoven fabric market.

English

English 中文简体

中文简体 русский

русский عربى

عربى