Spunbond vs. Spunlace: Key Differences in Nonwoven Fabric Technologies

Introduction

Nonwoven fabrics are integral to numerous industries, from hygiene products and medical supplies to filtration and automotive applications. Among the most prominent types of nonwoven fabric production technologies are spunbond and spunlace. While both processes create fabrics without weaving or knitting, they differ significantly in their raw materials, bonding techniques, texture, performance, and end uses.

1. Production Process

Spunbond

Spunbond is a thermoplastic polymer-based nonwoven fabric produced by extruding filaments from melted polymer granules (typically polypropylene, polyester, or polyethylene). The continuous filaments are laid randomly onto a conveyor belt and bonded through thermal, mechanical, or chemical methods—most commonly thermal bonding using heated rollers or calenders.

Steps:

Polymer melting

Filament extrusion

Web formation

Thermal bonding

Spunlace

Spunlace (also known as hydroentanglement) is made by mechanically entangling fibers using high-pressure water jets. The raw material is usually a blend of natural fibers (like cotton or viscose) and synthetic fibers (like polyester).

Steps:

Fiber blending and carding

Web layering

Hydroentanglement

Drying and finishing

2. Raw Materials

Spunbond: Mostly thermoplastic polymers (PP, PET, PE)

Spunlace: Natural fibers (cotton, viscose) and synthetic fibers (PET, PP)

3. Fabric Characteristics

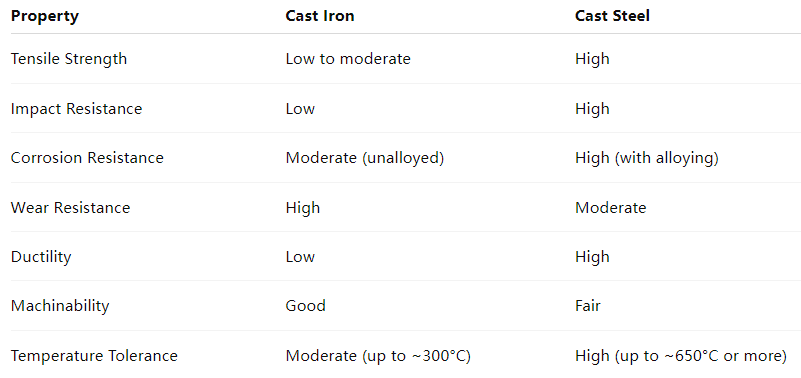

4. Performance Properties

Spunbond:

UV resistance (with additives)

High durability

Low cost

Hydrophobic unless treated

Spunlace:

Soft and breathable

Highly absorbent

Excellent drape and conformity

Costlier due to water and energy consumption

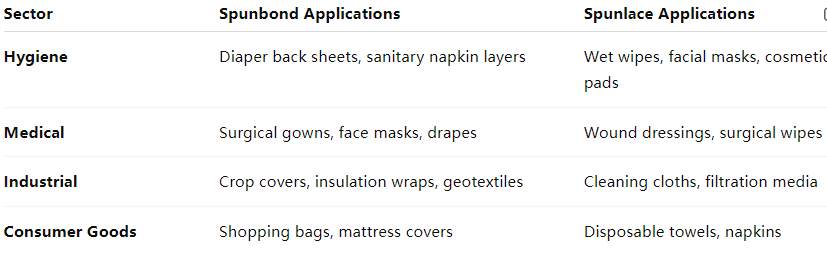

5. Applications

6. Environmental Considerations

Spunbond fabrics are typically less biodegradable due to the use of polypropylene or polyester, though recyclable.

Spunlace can be made from biodegradable materials like cotton and viscose, making them more eco-friendly but also more resource-intensive to produce.

7. Cost and Efficiency

Spunbond has lower production costs and higher throughput rates due to a simpler, faster thermal process.

Spunlace is more expensive due to water consumption, drying requirements, and slower processing speeds.

8. Choosing Between Spunbond and Spunlace

The right choice depends on your priorities:

Choose spunbond for durability, cost-efficiency, and structural strength.

Choose spunlace for softness, absorbency, and textile-like performance.

Conclusion

Spunbond and spunlace nonwoven fabrics serve different purposes despite falling under the same broad category. Understanding their fundamental differences in production, performance, and applications can help businesses make informed material decisions tailored to their product requirements and market demands.

English

English 中文简体

中文简体 русский

русский عربى

عربى