Sustainability in Manufacturing: How Nonwoven Spunmelt Machines Contribute to Eco-Friendly Production

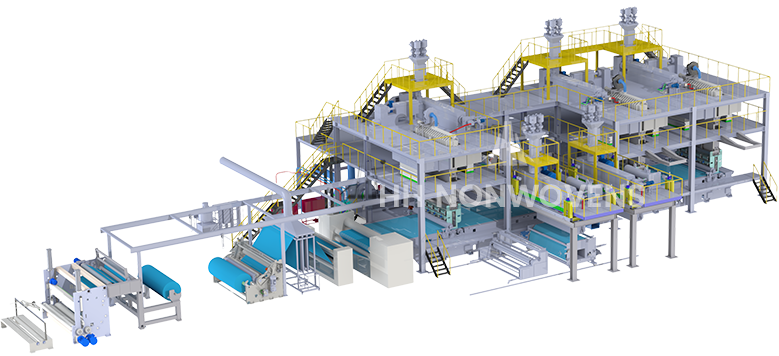

In recent years, sustainability has become a driving force in manufacturing, with industries looking for ways to reduce their environmental impact. A key player in this shift is the Nonwoven Spunmelt Machine, which offers numerous advantages in producing nonwoven fabrics that align with eco-conscious manufacturing practices. These machines are not only central to the production of high-quality, durable fabrics but also provide a sustainable alternative to traditional manufacturing methods that generate more waste and require more energy.

The Nonwoven Spunmelt Machine works by fusing synthetic fibers into nonwoven fabric, using heat and pressure to create durable products without the need for weaving or knitting. This process is highly efficient and minimizes waste by using raw materials more effectively. The ability to use recyclable polypropylene or biodegradable materials means that manufacturers can create products with a reduced carbon footprint, meeting both regulatory standards and consumer demand for more environmentally friendly options.

One of the most notable sustainable advantages of spunmelt technology is its ability to reduce water and chemical usage in the production process. Traditional fabric manufacturing methods, like weaving or knitting, often rely heavily on water and chemical treatments to prepare fibers. In contrast, nonwoven spunmelt machines do not require water in their production process, which significantly lowers water consumption. Furthermore, the lack of harsh chemicals involved reduces the impact on water bodies and the environment, making it a safer alternative for both workers and local ecosystems.

As industries, including hygiene, automotive, and medical sectors, increasingly turn to nonwoven fabrics, the role of the Nonwoven Spunmelt Machine becomes even more vital in producing materials that meet the rising demand for eco-friendly solutions. For example, the healthcare industry uses nonwoven fabrics for surgical gowns, masks, and bandages, all of which require high standards of hygiene and durability. By utilizing spunmelt technology, manufacturers can meet these demands while minimizing their environmental footprint—an attractive proposition for both consumers and regulatory bodies.

The ability to integrate recycled materials into the production process also adds to the sustainability of spunmelt fabrics. With the rise of circular economy principles, using recycled polypropylene or other sustainable raw materials ensures that nonwoven fabrics can be repurposed at the end of their lifecycle, reducing waste and encouraging the reuse of resources. By embracing this approach, manufacturers can play a significant part in reducing global plastic waste, which is one of the primary concerns in today’s environmental discourse.

Moreover, the compact nature of Nonwoven Spunmelt Machines helps reduce energy consumption during production. These machines are engineered for efficiency, and their streamlined process requires less energy compared to traditional methods. The result is lower production costs and a smaller carbon footprint. In industries where energy consumption is a major concern, this reduction can have a substantial positive impact on both the environment and the bottom line.

In addition to their environmental benefits, spunmelt machines offer economic advantages for manufacturers looking to optimize their operations. The efficiency of these machines translates to faster production cycles, which allows manufacturers to keep up with high-demand markets without sacrificing product quality. This helps businesses maintain a competitive edge while fulfilling their sustainability goals, making spunmelt technology an essential investment for future-focused companies.

Ultimately, the role of Nonwoven Spunmelt Machines in sustainable manufacturing cannot be overstated. By providing a more environmentally friendly production process that reduces waste, conserves resources, and integrates recycled materials, these machines help companies meet the growing demand for green manufacturing solutions. As industries continue to shift towards eco-conscious practices, spunmelt technology will play an increasingly pivotal role in shaping the future of nonwoven fabric production, allowing businesses to contribute to sustainability while also enhancing their operational efficiency.

This perfect balance of innovation and eco-friendliness makes the Nonwoven Spunmelt Machine a cornerstone of the sustainable manufacturing movement. By adopting this technology, manufacturers can not only reduce their environmental impact but also position themselves as leaders in the green manufacturing space, meeting both regulatory demands and consumer expectations for a cleaner, greener future.

English

English 中文简体

中文简体 русский

русский عربى

عربى