The Role of Automation and Industry 4.0 in Enhancing Nonwoven Fabric Manufacturing with SMMSS Machines

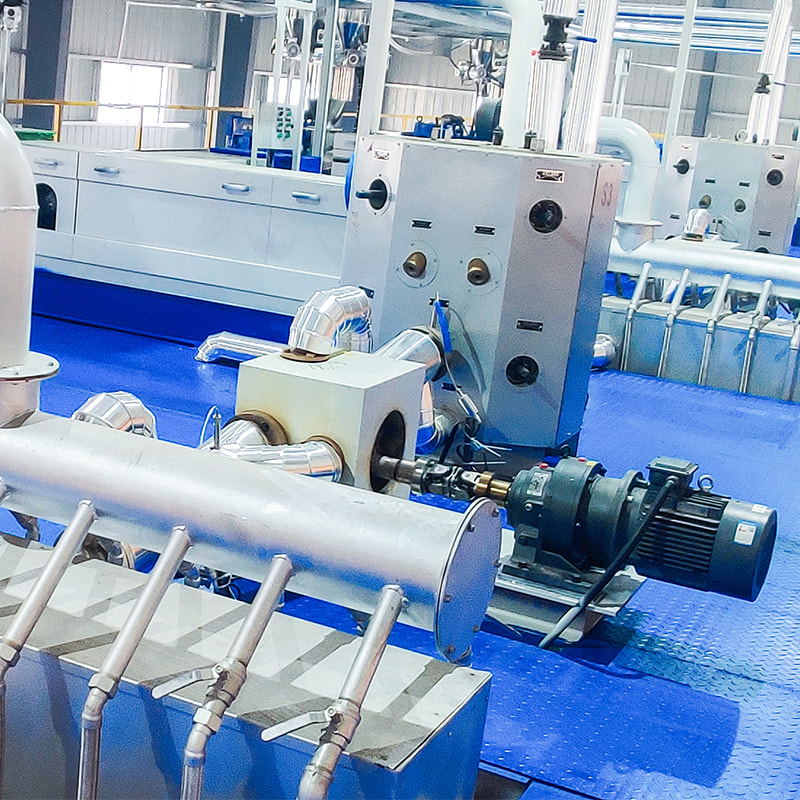

As the manufacturing landscape continues to evolve, automation and smart technology are transforming production processes across various sectors. For nonwoven fabric manufacturers, integrating automation into production lines—especially with cutting-edge equipment like the SMMSS nonwoven fabric machine—can dramatically improve efficiency, reduce human error, and increase production speed. These advancements are a direct response to the growing need for faster, more reliable manufacturing processes that can keep up with market demands for high-quality, cost-effective nonwoven fabrics.

One of the key benefits of automation in nonwoven fabric production is the ability to monitor and control operations remotely. With Industry 4.0 principles incorporated into machines like the SMMSS nonwoven fabric machine, manufacturers can access real-time data on machine performance, production output, and maintenance needs. This smart technology allows for predictive maintenance, meaning that potential issues can be detected and addressed before they lead to costly downtime. Through sophisticated sensors and analytics, manufacturers can ensure that their equipment is always running at optimal performance, leading to longer machine lifespans and higher product quality.

Automation also plays a critical role in improving the consistency of fabric quality. The SMMSS nonwoven fabric machine is designed to work seamlessly with automated systems that ensure uniformity in filament production, slitting, and fabric formation. By reducing the reliance on manual labor, the machine minimizes the possibility of human error that can result in inconsistencies in the final product. The precision provided by automated control systems guarantees that each batch of nonwoven fabric meets the desired specifications, whether it’s for medical, hygiene, or industrial applications.

Furthermore, Industry 4.0 technologies enable a higher level of customization and flexibility in production. With automated controls, the SMMSS nonwoven fabric machine can be programmed to adjust parameters such as production speed, filament denier, and fabric width to suit specific customer needs. This adaptability allows manufacturers to meet a wide range of requirements without the need for extensive retooling or production line downtime. As demand for specialized fabrics continues to grow, the ability to quickly switch between different fabric types without sacrificing quality or speed becomes a significant competitive advantage.

Integrating automation and Industry 4.0 technologies into nonwoven fabric manufacturing not only boosts production efficiency but also enhances the overall sustainability of operations. By optimizing energy use, reducing waste, and streamlining workflows, manufacturers can lower their carbon footprint and increase profitability. The SMMSS nonwoven fabric machine, equipped with advanced automation features, is a prime example of how embracing smart technology can transform production lines and position companies for success in a fast-paced, competitive market.

English

English 中文简体

中文简体 русский

русский عربى

عربى