When it comes to producing high-quality nonwoven fabrics, the raw material selection plays a crucial role in determining the overall performance of the spunbond nonwoven machine and the fabric it creates. Among the various materials used, polypropylene granule fiber grade with a Melt Flow Index (MFI) ranging between 30 and 40 is widely recognized as the ideal choice. This specific MFI range provides the right balance of flowability and strength, enabling the machine to produce consistent and durable spunbond fabrics tailored for a variety of applications. Understanding why this material grade matters can help potential buyers make informed decisions and optimize their production lines.

The Melt Flow Index is a critical parameter that measures the ease with which the polypropylene granules melt and flow during the extrusion process. For spunbond nonwoven machines, this parameter influences the formation of continuous filaments that make up the fabric. A polypropylene granule fiber grade with an MFI of 30-40 melts at an optimal rate, ensuring smooth extrusion without clogging or material degradation. This steady flow results in uniform fiber thickness and contributes to the fabric’s consistent weight and mechanical strength, which are vital for meeting industry standards.

In addition to the flow properties, the fiber grade’s molecular structure affects the tensile strength and elasticity of the spunbond fabric. Polypropylene granules within the MFI 30-40 range maintain a high molecular weight that delivers excellent strength and durability to the final nonwoven fabric. This ensures that the fabric withstands demanding conditions such as high tensile stress during processing and end-use applications like medical masks, hygiene products, or agricultural covers. Using a substandard raw material with a lower or higher MFI could compromise fabric quality and reduce the operational efficiency of the spunbond nonwoven machine.

From a manufacturer’s perspective, sourcing polypropylene granule fiber grade with the right MFI is also essential for machine maintenance and longevity. When the raw material melts too quickly or too slowly, it can cause buildup or wear in the extrusion components, leading to frequent downtime and costly repairs. By consistently using granules with MFI 30-40, the machine operates within ideal parameters, minimizing the risk of malfunctions and ensuring stable production output. This not only improves the machine’s return on investment but also builds trust with customers relying on dependable fabric quality.

Another advantage of this particular polypropylene grade is its compatibility with the automated control systems often integrated into modern spunbond nonwoven machines. Precise control over temperature and extrusion speed is easier to achieve when the material properties are consistent and predictable. This synergy between the raw material quality and the machine’s advanced components results in higher efficiency and less operator intervention, which is a significant benefit for industrial-scale fabric manufacturers looking for smooth, scalable production lines.

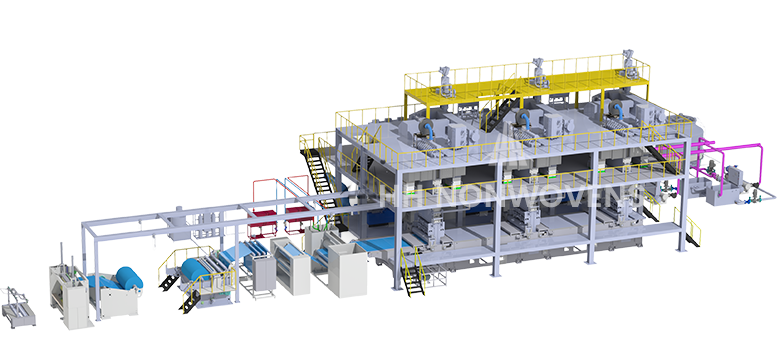

For businesses seeking a reliable spunbond nonwoven machine, partnering with a manufacturer that understands the importance of raw material specifications can make all the difference. At JIASHAN HH Nonwovens Machinery CO., Ltd, we emphasize the use of high-grade polypropylene granule fiber with an MFI of 30-40 to ensure our spunbond nonwoven machine deliver superior performance, fabric quality, and operational stability. Our expertise and commitment to quality help customers optimize their production lines, minimize downtime, and produce nonwoven fabrics that meet diverse market demands.

In summary, the polypropylene granule fiber grade with an MFI of 30-40 is a key factor influencing the efficiency and output quality of spunbond nonwoven machines. This material grade guarantees optimal melt flow, mechanical strength, and machine compatibility—crucial for producing consistent nonwoven fabrics suited for multiple industries. Choosing the right raw material not only enhances fabric performance but also safeguards your investment in advanced spunbond machinery, enabling your business to thrive in a competitive market.

English

English 中文简体

中文简体 русский

русский عربى

عربى