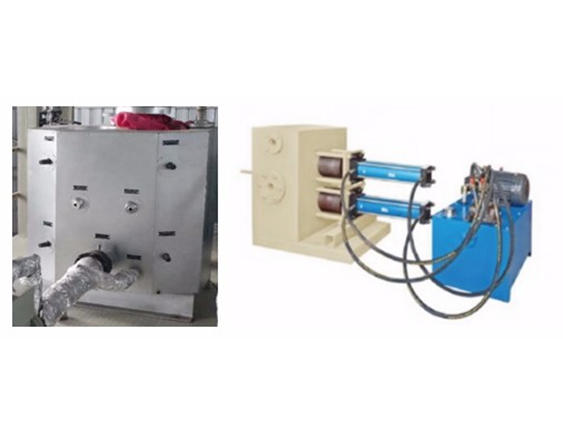

How are color master batch, antioxidant, and fire retardant additives incorporated into the process?The production of nonwoven fabric using the

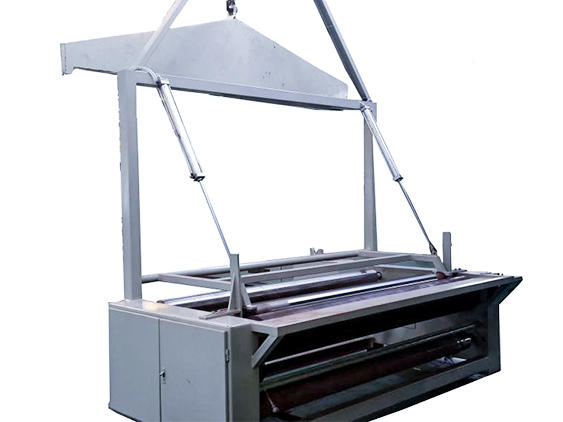

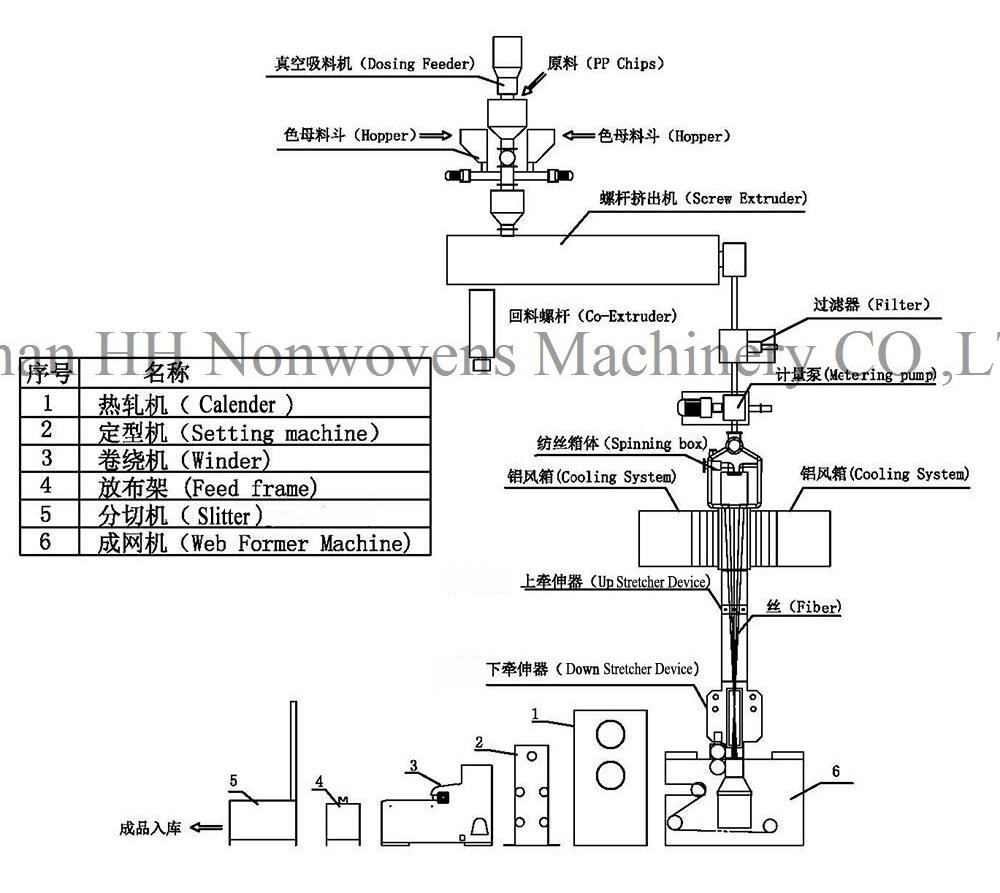

Single Beam S Spunbond Nonwoven Machine involves the incorporation of additives such as color master batch, antioxidant, and fire retardant. These additives play a crucial role in enhancing the characteristics and performance of the final fabric.

Color master batch is a concentrated mixture of pigments or dyes encapsulated during a heat process into a carrier resin. It imparts color to the nonwoven fabric, allowing for customization and versatility in product applications.

Incorporation Process:

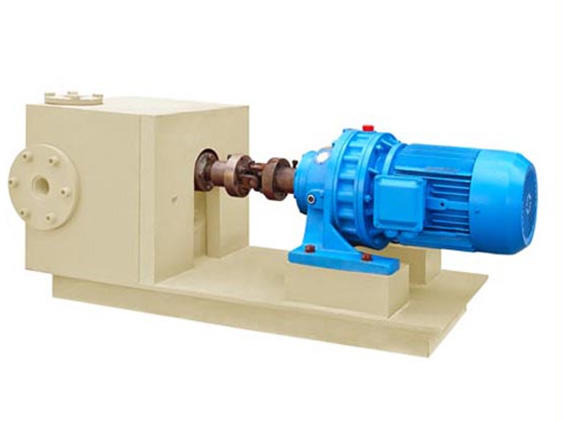

Feeding System: The color master batch is introduced into the extruder through a precise feeding system.

Extrusion Process: During extrusion, the master batch is uniformly dispersed within the polypropylene granule melt. This ensures an even distribution of color throughout the fabric.

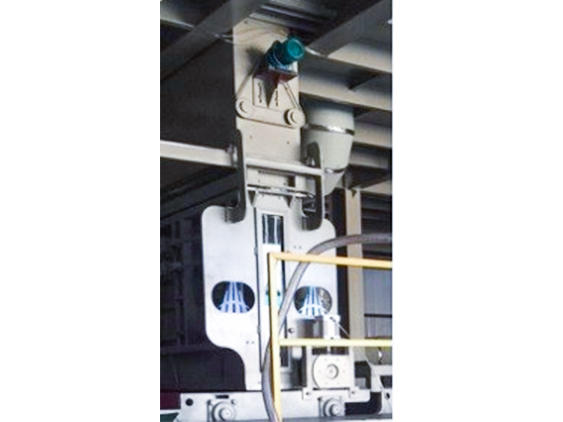

Spinning Process: The colored melt is then spun into filaments by the spinning beam, forming the basis for the nonwoven fabric.

Antioxidants are incorporated to prevent or delay the degradation of the polypropylene material due to exposure to heat, oxygen, or other environmental factors.

Incorporation Process:

Addition to Granules: Antioxidants are typically added to the polypropylene granules during the compounding phase.

Homogeneous Mixing: The granules, including the antioxidant, are thoroughly mixed to achieve a homogeneous blend.

Extrusion and Spinning: The blended granules, now containing the antioxidant, undergo extrusion and spinning processes. The antioxidant becomes an integral part of the spun filaments.

Fire retardants are essential for enhancing the flame resistance of nonwoven fabrics, making them suitable for various applications where fire safety is crucial.

Incorporation Process:

Addition to Polymer: Fire retardants are added to the polypropylene polymer either during the compounding of granules or directly during the extrusion process of

Single Beam S Spunbond Nonwoven Machine.

Uniform Distribution: The fire retardant is uniformly dispersed within the polymer matrix to ensure consistent flame resistance properties.

Filament Formation: During extrusion and spinning, the polymer blend containing the fire retardant is processed into filaments, forming the basis for the nonwoven fabric.

English

English 中文简体

中文简体 русский

русский عربى

عربى