Supply Ability:4 SETS/month

Port:Shanghai

Payment Terms:TT.LC,others

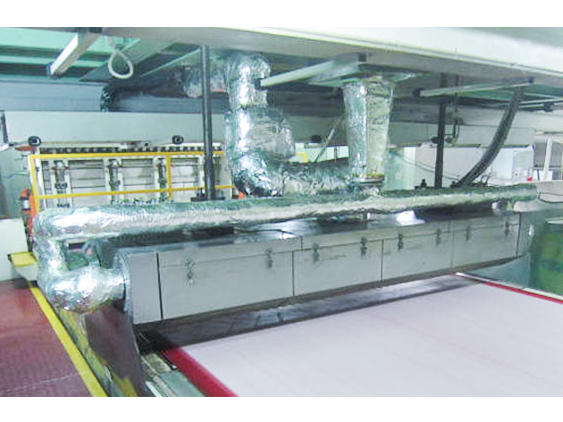

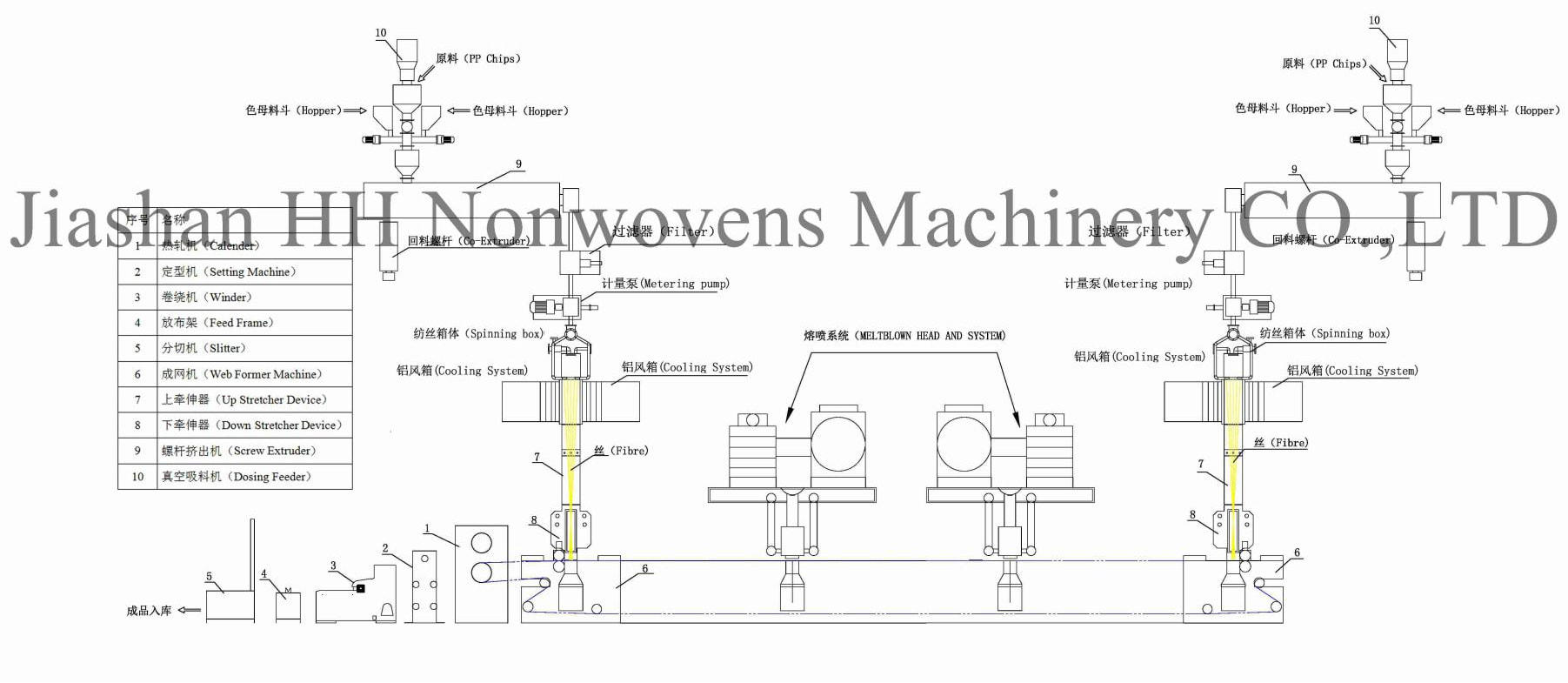

Application of the PP spunbond nonwoven fabric machine

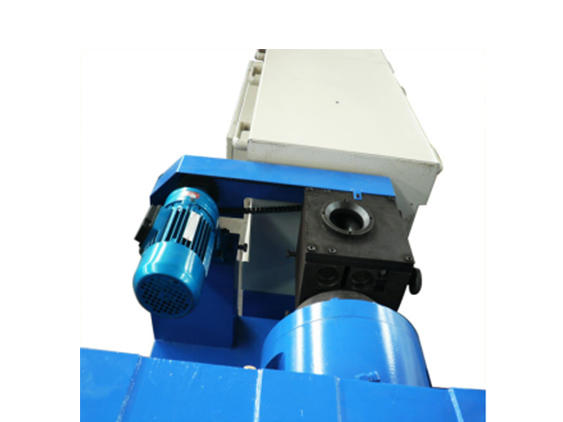

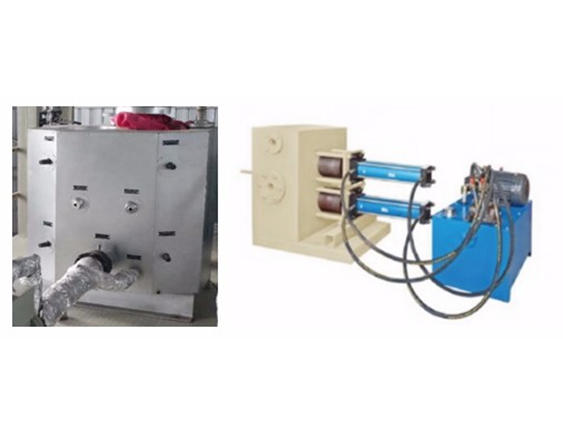

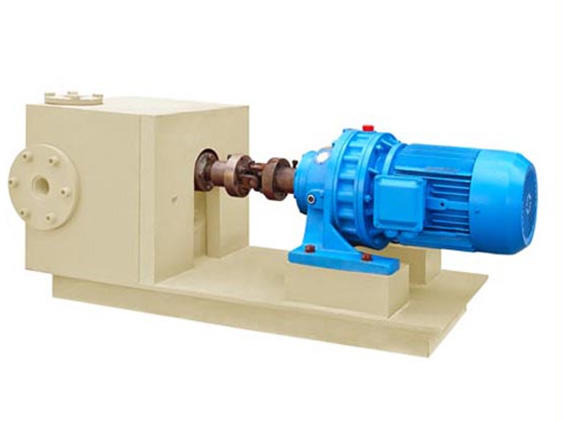

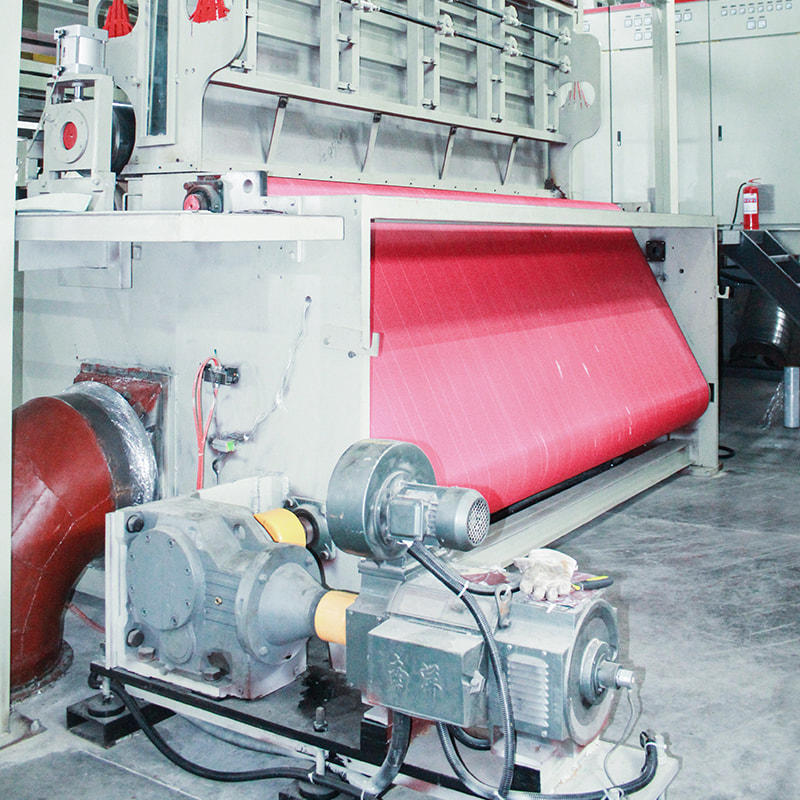

PP spunbond nonwoven fabric machine is used to produce pp spunbond nonwoven fabric.With slitter in our machine,the fabric can be cut into any width to fit different requirement.Machine running speed is 10-350m/min,filament denier:1.8-2.3denier

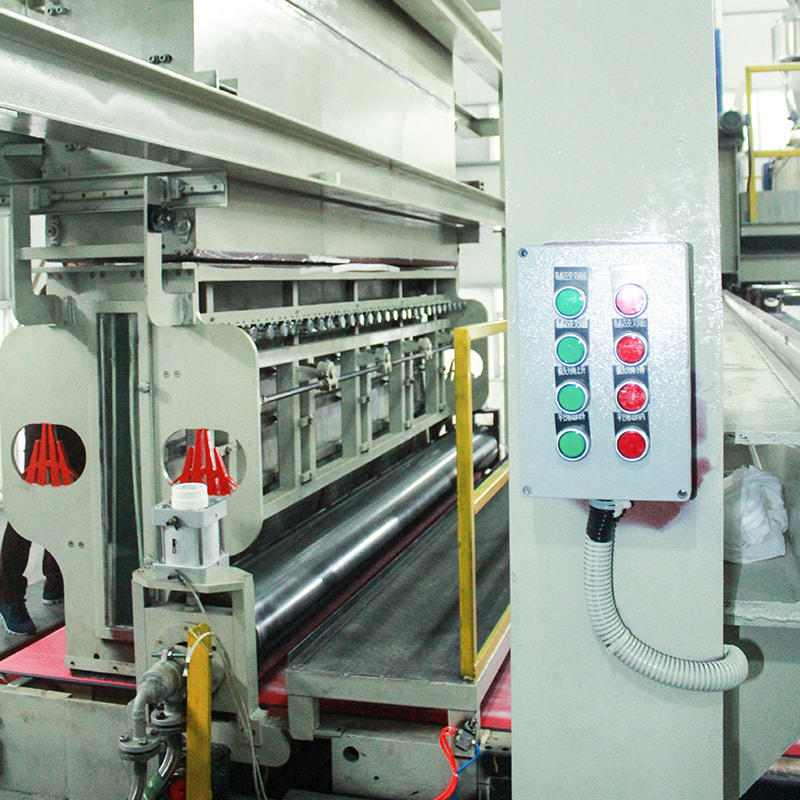

Use CNC to produce main parts of the pp spunbond nonwoven machine.Machine roller use dynamic balance machine to produce the rollers so as to make machine running in high speed.Main motors use Siemens motor,and use Siemens or ABB driver to control the whole machine.

After-sales Service Provided:

Video technical support, Online support, Field installation, commissioning and training, Engineers available to service machinery overseas

English

English 中文简体

中文简体 русский

русский عربى

عربى