Supply Ability:4 SETS/month

Port:Shanghai

Payment Terms:TT.LC,others

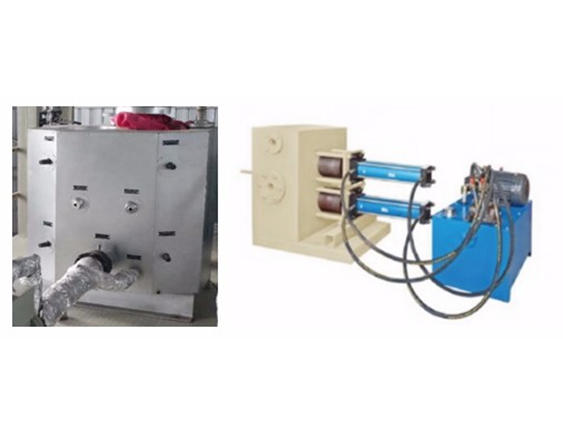

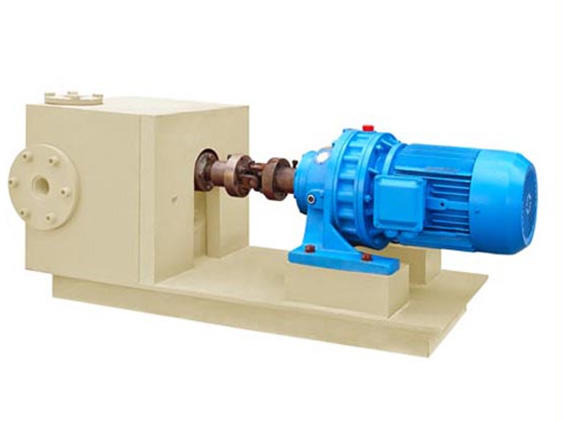

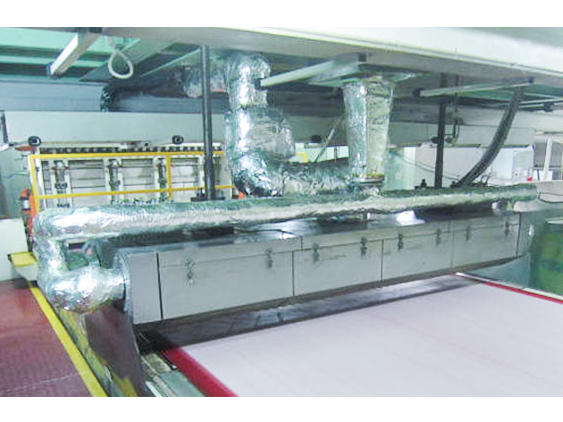

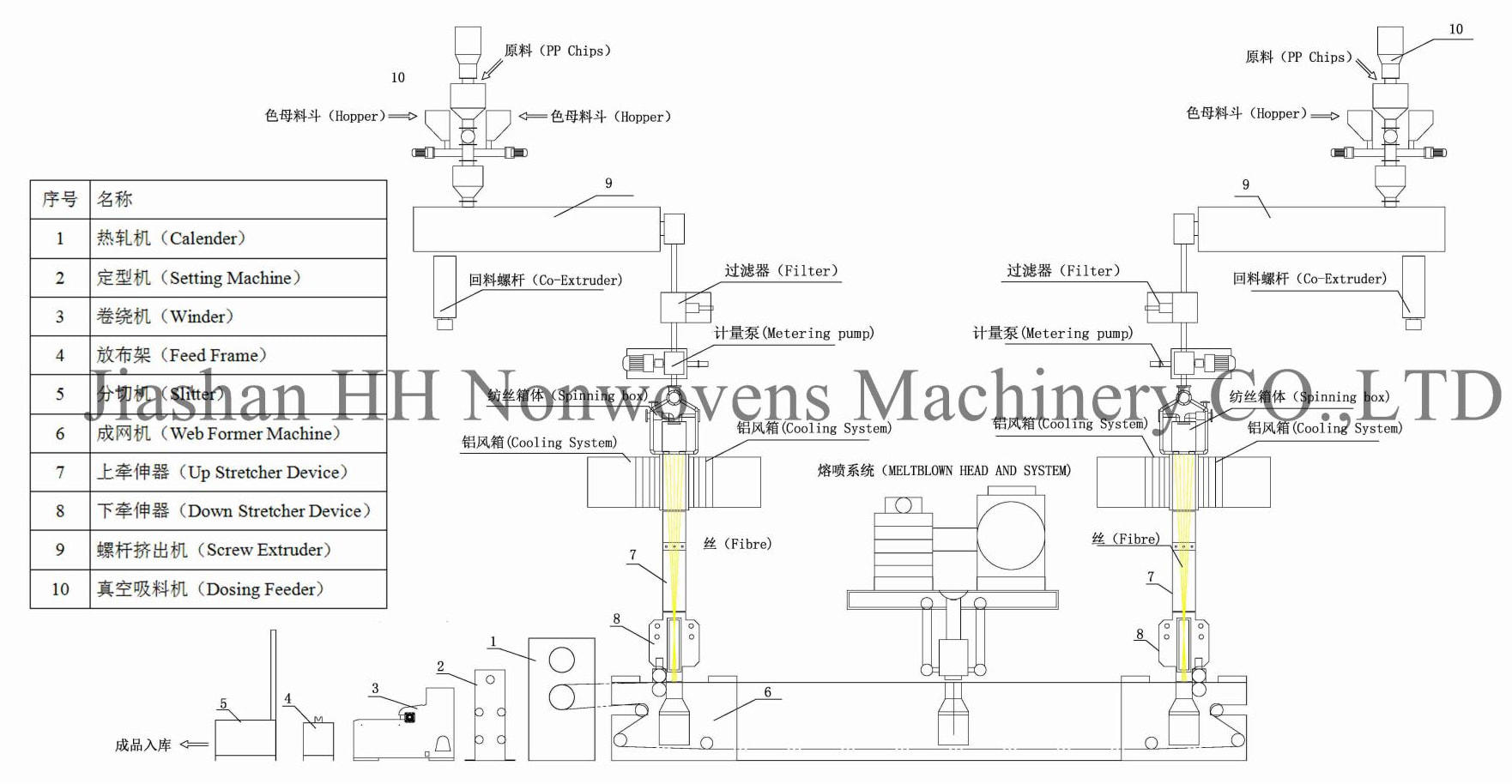

MACHINE TYPE:SMS (Spunbond+Melt Blown+Spunbond)

MACHINE SPEED:9-350 M/MIN

FILAMENT DENIER:SPUNBOND:1.5~2.5 D; MELTBLOWN:1.6~4μm

FABRIC WEIGHT:9~70GSM

OUTPUT:6-20 TON(Depends on machine effective width)

RAW MATERIAL:100% POLYPROPYLENE GRANULE FIBER GRADE; MFI 25-40 FOR SPUNBOND; MFI 800~1600 FOR MEL TBLOWN

WORKPLACE SIZE:35m*18m*12m

LABOR REQUIREMENT:7 WORKERS PER SHIFT,2 SHIFTS PER 24HOURS,TOTALLY 14 WORKERS

DELIVERY TIME:6 MONTHS

Application of the SMS (Spun-Melt ) nonwoven machine

The machinery is suitable to the production of nonwoven fabric by spun-laid and hot-rolled reinforcement.With PP as its main material ; color master batch, antioxidant,fire retardant as its additives to produce nonwoven fabric with different colors and different elements to fit the needs of different usages.This machine is able to produce SMS spun-melting nonwoven fabric , SS spunbonded nonwoven fabric,S spunbonded nonwoven fabric and M melt blown nonwoven fabric.Fabric from this machine can produce high quality face mask,diaper,napkin,high quality medical usage, shopping bag,packing,agricultural cover,rice bag.etc

English

English 中文简体

中文简体 русский

русский عربى

عربى